Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

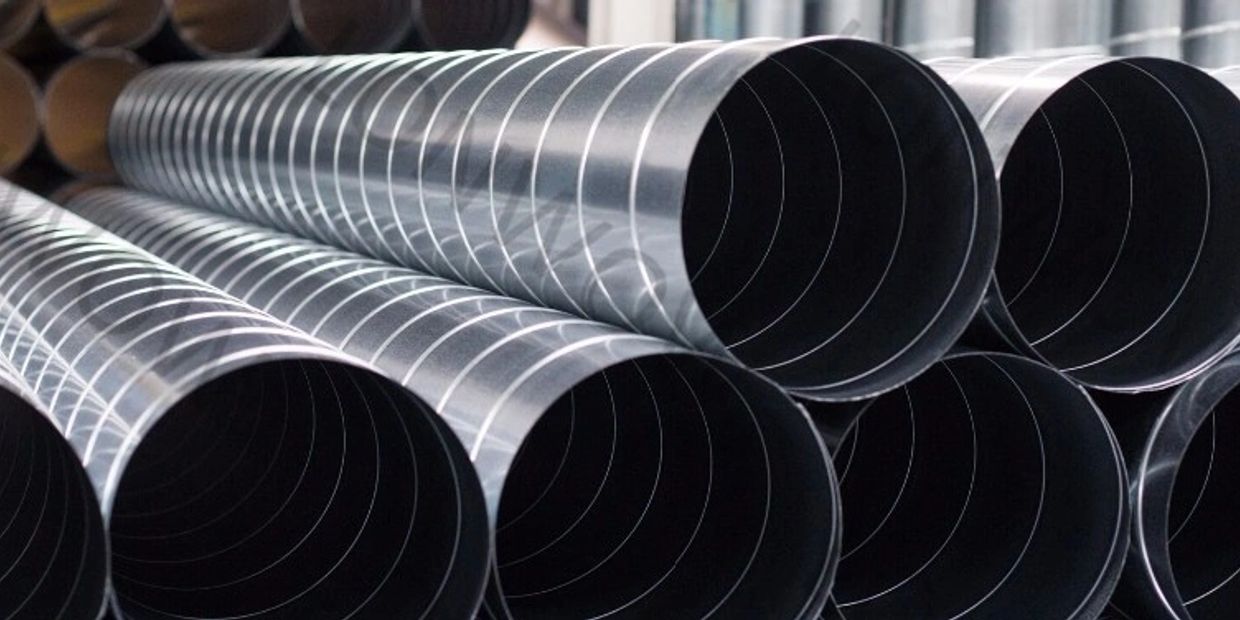

Spiral duct work has been widely promoted in the ventilation and air condition industries. It features low wind resistance, high effect, fine strength and rigidity, convenient installation, small space occupying, fine sealing and is easy to set-up.

Where most other types of ducting are formed from sheet metal, round spiral duct pipe is formed from a coil of sheet metal into a rigid steel tube with a 4-ply spiral lock seam. It has a relatively smooth interior for low friction loss with the grooved seam entirely on the outside. Typically, spiral duct is available in 6m lengths but shorter lenghts can be produced on request. Pipe sections can be joined together by using inset-off-set with barrel clamp, standard spiral pipe connectors or sheet metal screws.

Benefits of using Spiral Ducting

The round spiral wound ducting provides an airflow with almost no drag and resistance. Usually, round ducting pipes are preferred for air transportation. What makes spiral ducting unique is that they are lightweight. This does not compensate on the rigidness and strength of the pipe. As a matter of fact, it makes galvanised spiral ducting ideal for long duct runs. First, it cuts costs from purchasing spiral ducting supplies, because there is less material used in the manufacturing process, those duct pipes are usually cheaper. The second savings come from the less amount of supporting accessories needed to install a spiral ducting system. Again, because of their light weight, spiral duct pipes can span longer distances without the need for support.

Spiral Pipe has a resistance to crushing approximately 2 1/2 times that of longitudinal lockseam or welded pipe.